Introduction to Ford Industrial Engines

Understanding Ford Industrial Engines

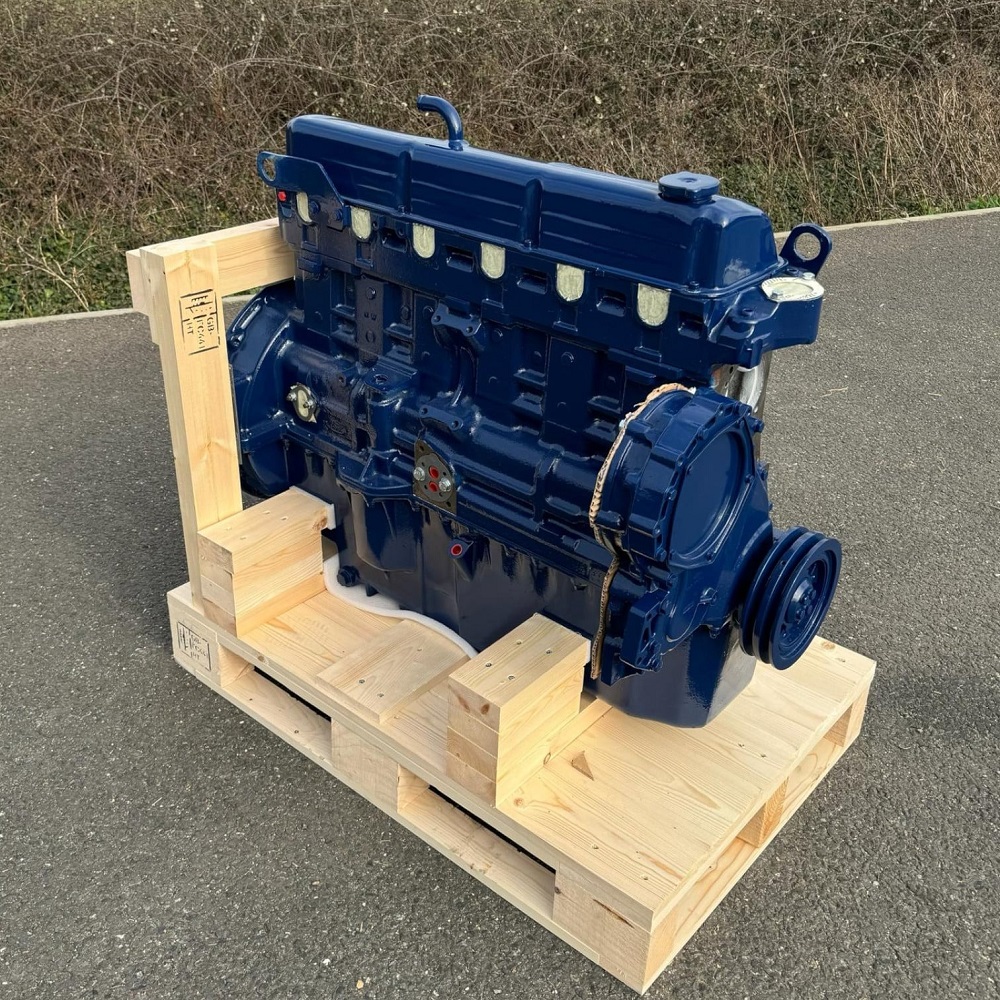

Ford industrial engine parts are renowned for their durability and performance. These engines power a wide range of machinery, from construction equipment to agricultural tractors. They are known for their reliability, efficiency, and ease of maintenance. Understanding the fundamental components of these engines is crucial for any owner or operator aiming to ensure longevity and performance.

Importance of Regular Maintenance

Regular maintenance is vital for the longevity of any engine, including Ford industrial engines. Neglecting maintenance can lead to costly repairs and decreased performance. Implementing a consistent maintenance routine can help prevent issues before they become significant problems. By understanding the specific needs of Ford engines, operators can maximize efficiency and reduce downtime.

Overview of This Guide

This guide will explore key maintenance tips for Ford industrial engine parts. The focus will be on crucial components, best practices for care, and common troubleshooting techniques. By following these tips, you can ensure your engine performs at its best for years to come. The information provided will be beneficial for both new and experienced operators.

Understanding Key Engine Components

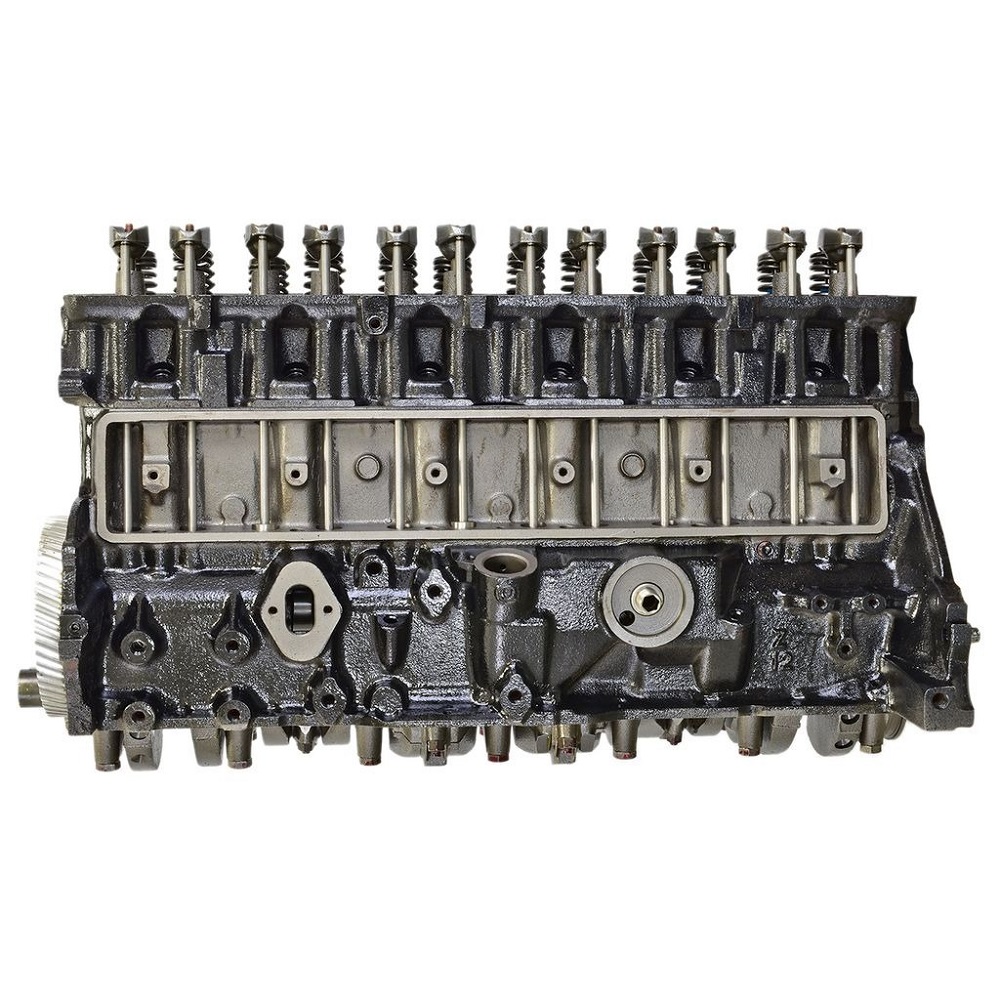

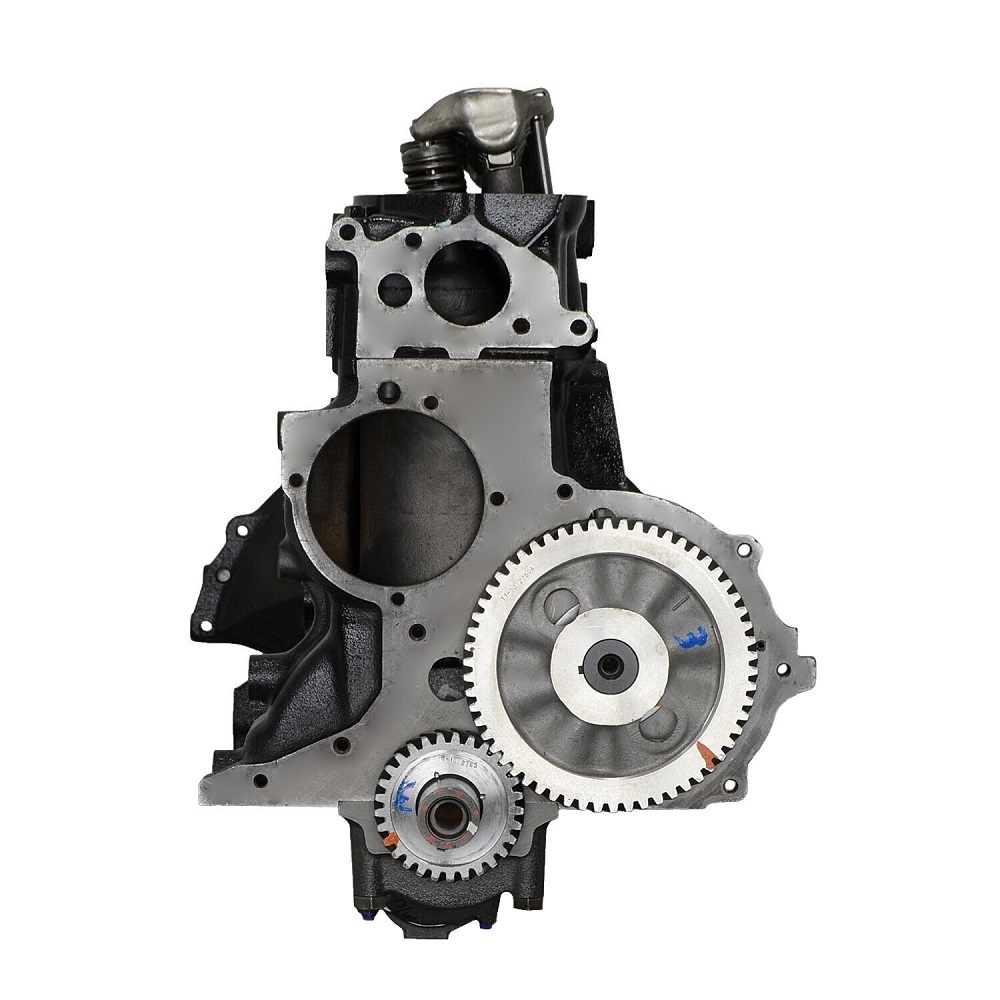

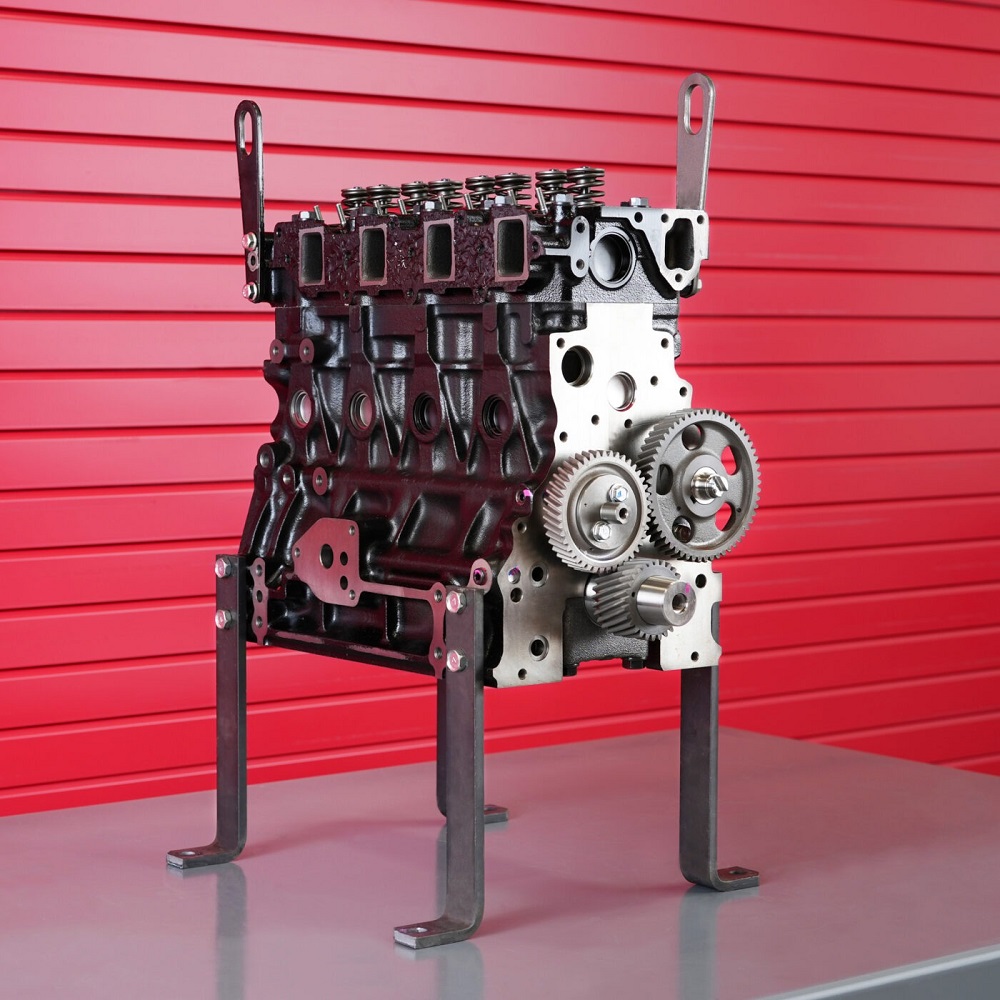

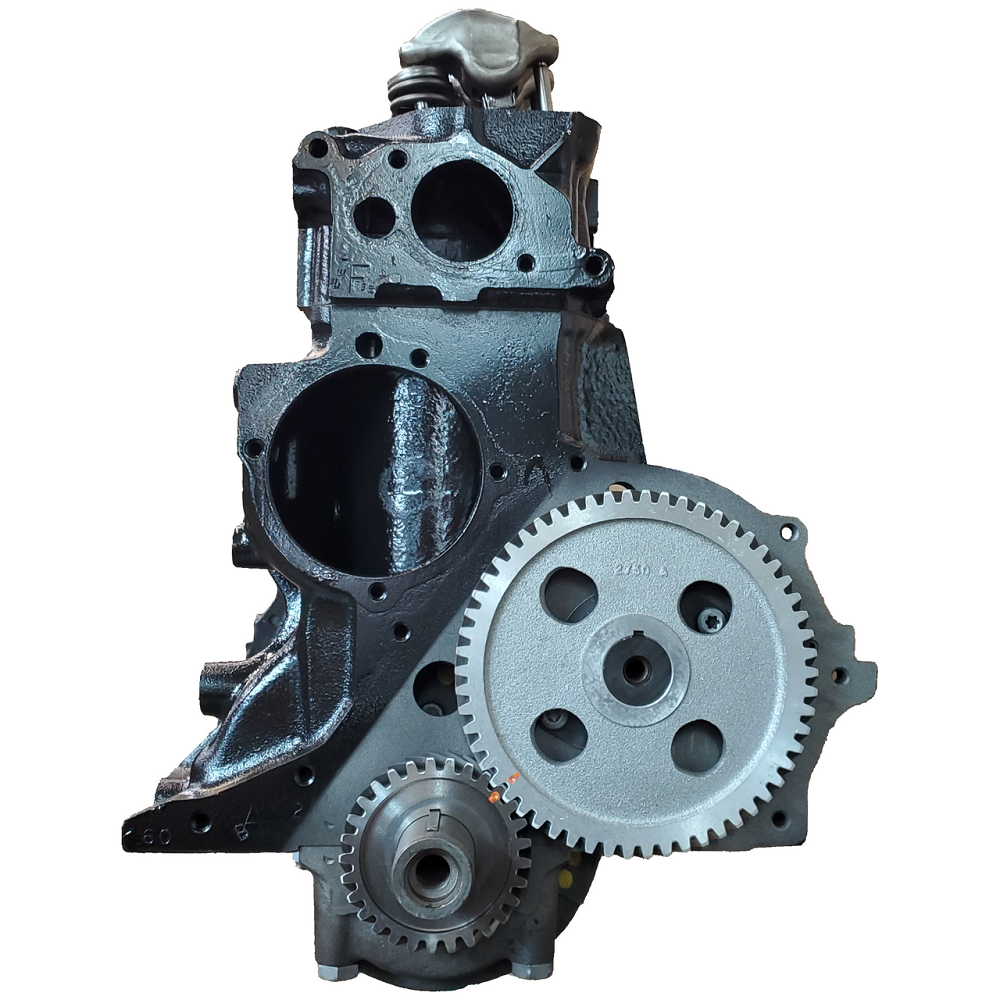

Engine Block

The engine block is the core component of any engine. It houses critical parts such as cylinders, pistons, and crankshafts. A robust engine block is essential for the overall stability and strength of the engine. Regular inspections for cracks or other damages can help prevent catastrophic failures.

Cylinder Heads

Cylinder heads play a vital role in engine functionality. They seal the combustion chamber and house the valves. Ensuring that the cylinder heads are free from cracks and properly sealed is crucial for optimal performance. Overheating or leaks can affect the engine’s efficiency, leading to severe damage.

Oil Pan

The oil pan is responsible for holding the engine oil. It ensures proper lubrication of moving parts. Keeping the oil pan free from debris and leaks is essential for maintaining oil levels. Regular oil changes and checks can help extend the life of the oil pan and, consequently, the engine.

Regular Oil Changes

Importance of Engine Oil

Engine oil lubricates moving parts and helps minimize friction. Clean oil is crucial for optimal engine performance. Over time, oil can break down due to heat and contaminants, leading to inadequate lubrication. Regular oil changes are crucial for maintaining engine health and longevity.

Recommended Oil Change Frequency

It is advisable to follow the manufacturer’s guidelines for oil change intervals. Generally, changing oil every 200-500 operating hours is a good practice for Ford industrial engine parts. However, factors such as operating conditions and load can influence this frequency. Keeping a maintenance log can help track oil change dates and ensure consistency.

Choosing the Right Oil

Selecting the appropriate oil type for your Ford engine is vital. Consult the owner’s manual for specific oil recommendations. Many Ford industrial engine parts perform best with high-quality synthetic oils that provide superior lubrication. Using oils that meet or exceed manufacturer specifications ensures optimal performance and protection.

Air Filter Maintenance

Role of the Air Filter

The air filter is crucial for maintaining engine efficiency. It prevents dirt and debris from entering the engine, which can cause wear and tear. A clean air filter contributes to better fuel efficiency and improved engine performance. Neglecting the air filter can lead to reduced airflow and decreased power output.

Checking and Replacing the Air Filter

Regularly inspecting and replacing the air filter is essential for engine health. It is generally advisable to check the air filter every 100 hours of operation. Replace it if it appears dirty or clogged. Many operators opt for reusable filters for their sustainability and cost-effectiveness.

Signs of a Clogged Air Filter

Common signs of a clogged air filter include decreased engine performance, unusual engine noises, and increased fuel consumption. Addressing these issues promptly can prevent more significant problems down the road. If you notice these symptoms, inspect the air filter and replace it if necessary.

Cooling System Care

Understanding the Cooling System

The cooling system regulates engine temperature and prevents overheating. It includes components such as the radiator, water pump, and coolant. Proper cooling ensures the engine operates at optimal temperatures, enhancing performance and longevity.

Regular Coolant Checks

Regularly checking coolant levels is essential for the cooling system’s efficiency. Low coolant levels can lead to overheating and engine damage. It is beneficial to check the coolant reservoir frequently and top off as needed. Additionally, always use the recommended coolant type for your Ford engine.

Flushing the Cooling System

Flushing the cooling system is an essential maintenance task. This process removes contaminants and debris from the system, ensuring optimal cooling. It is typically advisable to flush the system every two years or as recommended in the owner’s manual. Performing this task can prevent corrosion and extend the life of the cooling system components.

Fuel System Maintenance

Importance of Fuel Quality

Quality fuel is vital for engine performance. Contaminated or low-quality fuel can lead to engine knocking and reduced efficiency. Using high-quality fuel that meets or exceeds specification can help ensure optimal performance.

Regular Fuel Filter Replacement

The fuel filter prevents contaminants from reaching the engine. Regular replacement of the fuel filter is essential to maintain fuel quality. It is advisable to check and replace the fuel filter every 500 hours of engine operation or as specified in the owner’s manual.

Inspecting the Fuel Lines

Regularly inspecting fuel lines for leaks or wear is crucial. Damaged fuel lines can lead to leaks and decrease engine performance. Look for signs of cracking or fraying and replace any damaged fuel lines immediately. Maintaining the integrity of fuel lines ensures a steady supply of quality fuel to the engine.

Electrical System Check

Importance of Electrical Components

The electrical system in Ford industrial engine parts powers various components, including the ignition and fuel systems. Issues within this system can lead to performance problems. Regular checks can help identify potential issues before they lead to significant failures.

Battery Maintenance

Maintaining the battery is essential for reliable performance. Regularly check connections and terminals for corrosion. Clean terminals if necessary, and ensure that the battery is securely fastened. Keeping the battery charged and in good condition will help prevent starting issues.

Wiring Inspections

Inspecting wiring for wear and damage should be part of your maintenance routine. Look for frayed wires or loose connections. Any damaged wires should be repaired or replaced. Proper wiring ensures optimal electrical performance and prevents potential failures.

Exhaust System Care

Understanding the Exhaust System

The exhaust system helps expel gases produced during combustion. Proper function is essential for engine efficiency and environmental compliance. A malfunctioning exhaust system can lead to poor performance and increased emissions.

Inspecting Exhaust Components

Regularly inspect exhaust components for rust, leaks, or damage. Pay close attention to joints and connections where leaks are most likely to occur. Addressing small issues early can prevent larger, more costly repairs down the line.

Keeping the Exhaust System Clean

Regular cleaning of exhaust components can prevent carbon buildup. Consider using chemical cleaners or professional services to maintain cleanliness. A clean exhaust system ensures proper airflow and can improve engine performance.

Maintaining Belts and Hoses

Importance of Belts and Hoses

Belts and hoses are critical components in any engine. They transfer power and fluids throughout the engine. Regular inspections can catch wear and prevent failures that could lead to significant downtime.

Checking for Wear and Tear

Regularly check belts and hoses for signs of damage. Look for cracks, frays, or leaks. Replace any belts or hoses that show signs of wear. Ensuring these components are in good condition can help prevent unexpected breakdowns.

Keeping a Maintenance Schedule

Establishing a maintenance schedule for belts and hoses can help ensure they are regularly checked. This proactive approach can prevent costly repairs and downtime. Keeping records of inspections and replacements helps track the condition of these components.

Utilizing Genuine Parts

The Benefits of Genuine Ford Parts

Using genuine Ford parts ensures compatibility and quality. These parts are designed specifically for Ford industrial engine parts, guaranteeing optimal performance. While aftermarket parts might be cheaper, they can lead to performance issues and higher maintenance costs in the long run.

Where to Purchase Genuine Parts

Genuine Ford parts can be purchased through authorized dealerships and trusted suppliers. Always ensure that your source is reputable to avoid counterfeit parts. Purchasing from authorized dealers ensures that you receive high-quality components designed for your engine.

Understanding Warranty Implications

Using genuine parts can also impact warranty coverage. Many manufacturers require the use of genuine parts to maintain warranty eligibility. Always check the warranty terms and conditions to avoid any surprises down the road.

Keeping Records of Maintenance

Importance of Maintenance Records

Maintaining detailed records of all maintenance activities is crucial. These records help track what has been done and when. They can also assist in identifying patterns or recurring issues that may need attention.

What to Include in Maintenance Logs

Include information such as dates of maintenance, parts replaced, and any issues encountered. Keep receipts for parts purchased and services performed. This documentation can be invaluable when assessing the state of the engine or seeking warranty coverage.

Using Technology for Maintenance Tracking

Consider using apps or software to manage maintenance records. Many tools are available that make tracking and scheduling maintenance easy. Utilizing technology can simplify the process and ensure nothing is overlooked.

Conclusion: Ensuring Longevity for Ford Industrial Engines

The Importance of Proactive Maintenance

Proactive maintenance is key to ensuring the longevity of Ford industrial engine parts. Regular inspections and timely replacements can prevent minor issues from escalating into costly repairs. Staying ahead of maintenance tasks will keep your engine running smoothly for years to come.

Investing in Quality and Reliability

Investing in genuine parts and reliable maintenance practices ensures optimal performance. The right components and consistent care can significantly extend the life of your engine. By committing to quality, you will save money in the long run and enhance operational efficiency.

Empowering Operators for Success

Understanding maintenance best practices empowers operators and owners alike. By implementing these strategies, you can achieve better performance and reliability from your Ford industrial engine parts. Take the time to familiarize yourself with these tips, and you will reap the benefits of a well-maintained engine.